- > You are in Bartz

- > TBM

- > Loading Tools

Bartz new website

![]() We release the new website of Bartz!

We release the new website of Bartz!

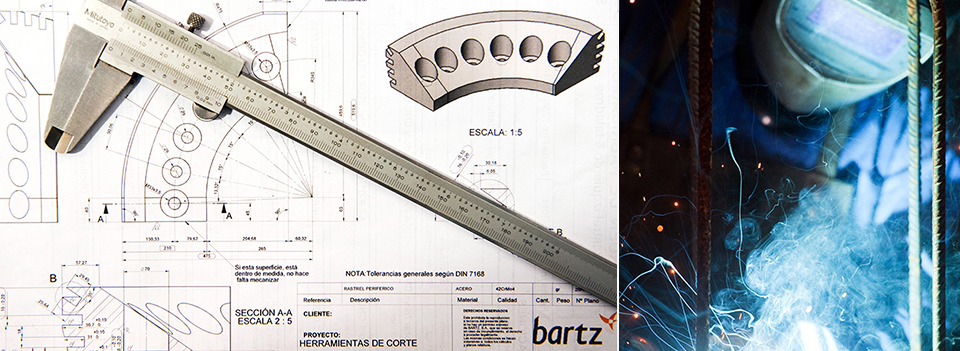

Loading Tools

As important as digging the ground, is evacuating the excavated material while minimizing the redrilling, therefore the loading tools are crucial for an optimal performance in the excavation.

When Bartz manufactures loading tools, in most cases, uses a body of carbon steel alloy with mechanical characteristics superior to the 100 - 115 Kg/mm2 and a hardness at the core higher than 35 HRc.

In addition, for a greater protection of the loading tools, BARTZ incorporates an anti-wear hard facing with a Chromium Carbide base that brings a high abrasion resistance in the most exposed areas of the loading tool, with a hardness between 60 and 80 HRc.

For even more demanding anti-wear requirements, Bartz incorporates into special areas a new method of anti-wear TIG hard facing getting in addition to a high abrasion resistance, a higher levels of elasticity welding, that performed through traditional MIG method.

To achieve the highest abrasion and wear resistance, Bartz includes tungsten carbide widias to the loading tools (92.2% CW - 7.8% Co either 89% CW - 11% Co) exceeding 2400 N/mm2 strength resistance and a hardness of about 1370 HV30. To ensure a secure joining between widia and body of the loading tools, we weld the widias using flush AG 304 (40% silver) in our controlled atmosphere furnace oven.

ES

ES EN

EN